| HOME | APPLICATIONS | SPACING & SELECTION | DIMENSIONS | MOUNTING | CONTACT US |

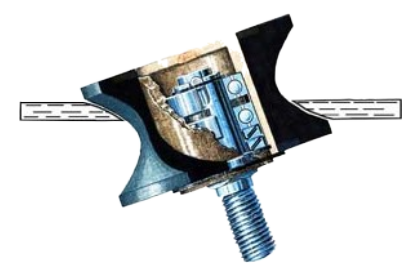

The GUIDLER®, a Guide Idler and Conveyor Belt Tracking Guide, was developed during the 1940's to assure reliable Belt Conveyor Tracking in the following industries: Coal, sugar, salt, mineral mining, cement, sand and gravel, smelting and refining, crushed stone, iron and steel, coal fired power plants, paper, brick, lime, gypsum, potash, fertilizer, roofing, baking, food manufacture, grain, abrasives, glass, asphalt, tire manufacture, chemicals, soda ash, tidal and river docks.

Attempts to control tracking with a conventional cylindrical guide idler or typical conveyor belt tracking guide are usually unsatisfactory because the lateral forces acting on the belt exceed the belt's resistance to curling as it makes point contact with the guide. Severe belt damage is the result. When properly inclined 30° in direction of belt travel our Guide Idler and Conveyor Belt Tracking Guide provides:

|

Subsequent minor

refinements over the past 70 plus years by the Knapp family has resulted

in the GUIDLER'S use world-wide. Improvements

have only been incremental - proof that the original design was almost

perfect in every respect.

Subsequent minor

refinements over the past 70 plus years by the Knapp family has resulted

in the GUIDLER'S use world-wide. Improvements

have only been incremental - proof that the original design was almost

perfect in every respect.